Industrial IoT normally conjures up an image of inanimate assets, machines and devices that are monitored by sensors sending data to an analytics layer. This layer in turn provides actionable insights on overall health, maintenance needs, and useful life associated with the asset.

Dr. Madhusudan Pai leads IoT partnership initiatives for Wipro Digital. Dr. Pai, passionate about driving new collaborations and partnerships at the confluence of the physical and digital worlds, works closely with the partner ecosystem to co-innovate and define go-tomarket strategies. He drives IoT initiatives by leveraging his extensive past involvement in product strategy, product design, engineering consulting and delivery. Dr. Pais domain expertise spans the aviation, energy, aerospace, and heavy manufacturing industries.

The CWSO testbed showcase featured a compelling solution: the Aruba Meridian-powered Location Services offering from Aruba Networks. We successfully demonstrated a combined solution integrating Meridian BluDot way-finding with Aruba Bluetooth Low Energy (BLE) Beacons much like an indoor GPS in the showcase area. In the demo, the Aruba Meridian and BLE Beacon technology provides turn-by-turn directions with BluDot that guides the worker from his or her current location to a safe exit point.

An engaging panel discussion on challenges and opportunities in using IoT for Worker Safety

IoT is undoubtedly an ecosystem play. The IoT architectural stack is complex and spans multiple layers: edge layer, connectivity layer, platform layer, and enterprise application layer. Creating a compelling and comprehensive end-to-end IoT solution requires two or more companies from the vast IoT partner ecosystem to converge on a closely-knit partnership that delivers on every layer of the solution stack. The partnership among Wipro, HPE, and Aruba Networks demonstrated just such a solution at the IoT Solutions World Congress (SWC) 17 in Barcelona: the Connected Worker Safety and Operations (CWSO) testbed showcase, which was judged among thetop 3 most impactful testbedsat the event.

The effectiveness of the CWSO worker safety solution depends on its ability to provide actionable insights rapidly especially at an oil rig or a remote construction site, where perhaps the only connection to the rest of the world is by satellite. Companies strive to avoid large data transmissions to the cloud via satellite connection as they can be expensive. The way to avoid sending large amounts of sensor data to the cloud is to use analytics capabilities very close to the edge the so-called edge compute paradigm. The CWSO showcase displayed a vision of how HPEs Converged Edgeline servers can enhance workplace safety through edge compute capabilities. For instance, the edge compute capability can detect a workers fatigue levels by analyzing video feeds or worker heart rates and issue alerts to the worker or the command center about any imminent hazardous situations.

There are several key technologies in Wipros worker safety solution. In the edge layer, Wipro showcased two key devices a smart helmet and a smart watch. The smart helmet includes multiple sensors for fall, hazardous gas, and pressure (to detect if a worker is wearing the helmet in hazardous areas), in addition to Wi-Fi or Bluetooth Low Energy-based worker localization capabilities. The helmet also features an identification system that registers a helmet to a particular worker. Complementing the helmet is the smart watch that provides timely alerts to workers to comply with safety standards. For example, if the worker removes the helmet in a hazardous location, the smart watch displays an alert reminding him or her to put the helmet back on. The watch also doubles as a heart-rate monitor.

The panel discussion on these engaging questions probed the nuances associated with the bigger picture around IoT for worker safety and served as a fitting culmination of the joint efforts on the CWSO testbed showcase by HPE, Aruba Networks, and Wipro at IoT SWC 17.

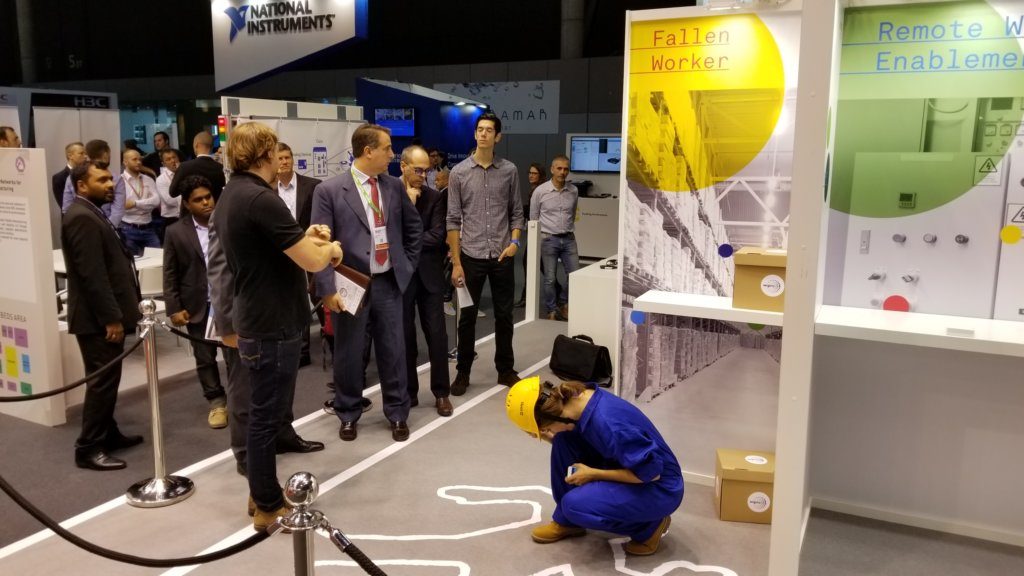

A demonstration of a fallen worker. A worker fall triggers an alert with the operations command center.

Connected Worker Safety mobile app powered by Aruba Meridian built for the IoT SWC showcase.

An immersed audience admiring the struck-by alert displayed on the mobile device.

Worker safety is a prime concern for industries around the world. According to the International Labor Organization, 2.3 million people worldwide die annually from occupational illnesses or accidents. Every day, there are 860,000 occupational accidents that lead to injuries. Overall, the direct and indirect costs of such accidents are estimated to be around US $2.8 trillion worldwide.

Workplaces have many hazards heavy moving equipment, overhead cranes, and toxic gas cylinders, to name just a few. Using the Aruba Beacon technology, we showcased solutions that send alerts to workers mobile devices, warning them of their proximity to such hazards.

The CWSO testbed showcase specifically demonstrated how smart technologies can improve worker safety and well-being while facilitating safe work practices and compliance to safety standards. Adoption of these technologies would therefore result in safer and more productive worksites.

IoT for Worker safety is becoming increasingly important in industries that are measured by their safety practices, workplace injuries, and safety compliance. I moderated a panel discussion on Worker Safety in Hazardous Environments with Dr. Colin LAnson from HPE, Brian Massey from IBM, Laura Tordera from Ferrovial Agroman, and Dr. Sanjoy Paul from Wipro. The panel participants shared their experiences on the challenges and opportunities in the adoption of technology for worker safety in industrial worksites.

To show how the CWSO solution enables safe worker operations and improves productivity, Wipro demonstrated a pair of augmented reality (AR) glasses. Enabled by WiFi, these glasses allow for real-time communication between a remote worker and a subject-matter expert at a command center. The AR glasses feature a speech-to-text capability and a front-facing video camera that provides a first-person point of view for the support personnel at the command center. Industries can deploy AR glasses in many ways: to support workers in the field who may be not be sure how to execute a task safely, or to assist new hires in unfamiliar situations that are not necessarily covered in a formal training program. AR technology can also give the worker important information about the environment such as proximity to high-voltage power lines or slippery floors.

A standard emergency procedure at worksites directs workers to follow a prescribed route to the safest exit point. How can technology guide a lone worker along the correct route to safety in an emergency? And how can technology direct emergency response teams along the quickest path to, for example, a fallen worker who needs immediate attention?

But what about the human asset? Can we use similar sensors to monitor worker safety and prevent injuries or worker fatality at an industrial worksite? The CWSO showcase at IoT SWC 17 unmistakably demonstrated that the answer is an emphatic Yes!

For further details on Wipros Connected Worker Solution, see:Wearables and Connected Workers: How Manufacturing Will Change Forever.

Wipro also showcased the Connected Worker Platform (CWP) featuring the device management layer, which onboards and manages these edge devices. This application delivers sensor data to an analytics layer, which displays insights on safety compliance on the CWP dashboard.

Director of Global IoT Partner Engineering

Director of Global IoT Partner Engineering

An important issue that we discussed was about privacy: when sensors are affixed to workers, privacy concerns invariably emerge. How will industry weigh IoTs enhanced ability to improve worker safety against concerns of worker privacy? Common sense dictates that safety trumps privacy having a worker return home to his or her family at the end of the day is undoubtedly more important than a potential incursion on privacy. A robust, effective, and affordable IoT solution that anonymizes worker privacy while still achieving worker safety goals and facilitating safety compliance will obviously benefit this debate. The discussion also addressed the costs associated with implementing IoT solution for worker safety at an industrial site how will industry measure the return-on-investment for such deployments? With the increasing popularity of augmented reality and virtual reality use-cases in workplaces, we discussed how we can leverage these technologies to facilitate worker safety.

Completing the three-tier CWSO architecture is the enterprise-level application layer that provides reports on worker safety, compliance, health, and location. These enterprise applications form a core component of the Workforce Operations Command Center which provides critical and timely information on worker status to support-center personnel and emergency response teams.