Collects process inputs and ambient conditions and predicts anomalous conditions

IBM Iot for Manufacturing solutions

Continuously monitors operator actions and advises the operator on the right set of actions to take

IBM IoT for Manufacturing solutions enable manufacturing plants to use IBM Watson IoT capabilities that exploit the potential of Internet of Things (IoT) and advanced analytics for improved equipment effectiveness. By infusing intelligence into manufacturing equipment and adopting new capabilities such as cognitive computing, IBM IoT for Manufacturing solutions offer deeper insights into manufacturing processes and unlock the true value of production assets. The intelligence, connectivity, and analytics provided by IoT for Manufacturing offerings give manufacturing organizations a means to obtain a more detailed and accurate understanding of factors that affect plant throughput, cost, and quality.

Learns optimal plant operating parameters from historical plant process parameters, process outputs, plant operator actions, and equipment maintenance details

IBM Acoustic Insightsenables organizations to use plant and operation sounds to automatically detect anomalies and defects and identify product quality issues. This helps quicken the highly skilled process of acoustic (sound) inspection for product quality tracking, helping to increase yield, reduce scrap, and reduce human inspection time. Through the use of sound analysis, you can:Identify defects in finished productsMonitor and track anomalies in in-process products

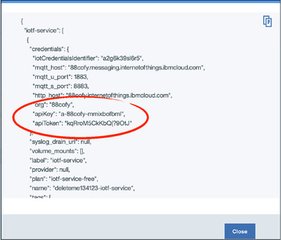

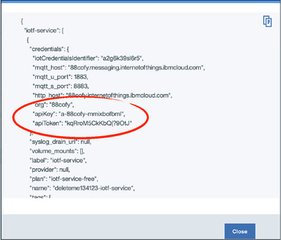

IBM Plant Advisoris a Cloud Service offering and part of the IBM IoT for Manufacturing suite of products. Plant Advisor employs advanced machine learning techniques to learn continuously from data generated by plant processes and operator actions.It predicts plant performance degradations and calculates the operating parameters and actions that will optimize plant performance for the current situation. Plant Advisor tackles plant performance loss due to operator judgement and lack of competence as it prescribes operator actions based on facts and data. Plant Advisor retains company knowledge and expertise and enables manufacturers to attain high performance consistently, thereby potentially saving millions of dollars per year.

Plant Advisor has analytical models that optimize each process (cement grinding, aluminum smelting, and so forth). Each machine that delivers the process being optimized is counted as an asset.

Prescribes the right parameter set-points for the given situation that would optimize throughput energy and quality

IBM Plant Advisoris a Cloud Service solution that advises manufacturing plant operators and process engineers on the best fit operating parameters that can yield lower energy cost while maximizing throughput at optimal quality.

IBM Acoustic Insights, a Cloud Service solution on SoftLayer, helps monitor product quality using sound. Sound inspection for product quality and anomaly detection is a key step in manufacturing. Quality problems can surface throughout the manufacturing process. Quality is monitored by inspecting different attributes of the finished product, such as finish measurements, visual inspection, and sound or audio inspection. Such inspection typically requires highly trained, skilled personnel who are able to detect anomalies and product defects based on the sound pattern and quality. Acoustic Insights solution can be trained to learn from quality inspectors and SMEs to identify product quality issues and anomalies based on sound patterns.